In the realm of food production, maintaining stringent hygiene standards is paramount to ensure consumer safety and uphold quality. The introduction of Cog-Veyor systems has revolutionized material handling within the food industry, offering a blend of efficiency and impeccable hygiene that traditional conveyor systems often struggle to match.

Understanding Cog-Veyor Systems

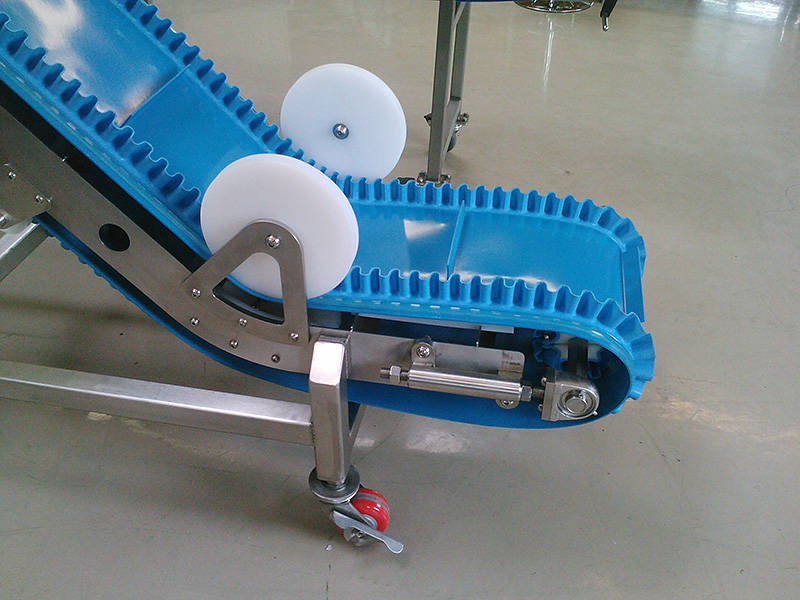

Cog-Veyor systems stand out in the food industry for their unique design and functionality. Unlike conventional conveyors with flat belts, Cog-Veyors utilize interlocking cogs or gears to transport products along the production line. This design minimizes direct contact between the belt and food items, reducing contamination risks significantly.

Hygiene Advantages of Cog-Veyor Systems

The hygienic superiority of Cog-Veyors stems from their design, which mitigates the risk of cross-contamination. The absence of flat surfaces on belts reduces areas where food particles can accumulate, preventing bacterial growth. Additionally, the open structure of these systems allows for thorough cleaning and sanitation, ensuring compliance with strict industry regulations.

Precision in Food Handling

Cog-Veyor systems excel in precision handling of food products. The interlocking cogs provide stability and accuracy in product transportation, minimizing product shifting or slippage. This precision is especially beneficial for delicate food items or those requiring specific positioning along the production line.

Resilience to Environmental Factors

Cog-Veyor systems are engineered to withstand harsh environmental conditions commonly encountered in food processing environments. They are resistant to moisture, extreme temperatures, and harsh cleaning chemicals, ensuring durability and maintaining hygienic standards over prolonged use.

Reduced Downtime for Cleaning and Maintenance

Efficient cleaning and maintenance schedules are crucial in the food industry. Cog-Veyor systems facilitate streamlined cleaning routines due to their design, allowing for quick disassembly and access to all components. The reduced downtime for cleaning and maintenance not only enhances hygiene but also ensures continuous production flow.

Compliance with Stringent Standards

In an industry governed by rigorous regulations and standards, Cog-Veyor systems stand as a testament to adherence to stringent guidelines. These systems align with various industry-specific standards, such as Hazard Analysis and Critical Control Points (HACCP) and Good Manufacturing Practice (GMP), ensuring safe and hygienic food processing practices.

Application in Various Food Segments

Cog-Veyor systems find applications across multiple segments of the food industry. From meat and poultry processing to baked goods and dairy, their versatility allows for efficient handling of diverse food products. The ability to customize these systems to cater to specific food production needs further enhances their value.

Sustainable Hygiene Solutions

Beyond their hygienic advantages, Cog-Veyor systems offer sustainable solutions. Their efficient design minimizes water and chemical usage during cleaning processes. Additionally, their durability and longevity contribute to reduced material waste and lower maintenance requirements, aligning with sustainable practices in food production.

Embracing Future Innovations

As technology evolves, so does the potential for further innovation in Cog-Veyor systems. Advancements in materials, automation, and sanitation techniques continue to enhance these systems, paving the way for even more hygienic and efficient solutions in the food industry.

Cog-Veyor systems have emerged as game-changers in the food industry, elevating hygiene standards while optimizing efficiency in material handling. Their innovative design, precision, and resilience to environmental factors make them a standout choice for food processors aiming to uphold the highest standards of cleanliness and safety. By embracing these systems, the food industry not only ensures consumer well-being but also strides towards a more efficient and sustainable future in food production.

Upgrade your food processing standards with Cog-Veyor Systems, your GTA destination for top-tier positive drive conveyor belts. Elevate hygiene and efficiency in food handling—contact them today for innovative solutions!