Metal fabrication plays a crucial role in various industries, from construction and automotive to manufacturing and design. Whether it’s custom sheet metal work, welding repairs, or the creation of high-strength components, skilled metal fabricators ensure precision and durability. In Toronto, where quality and efficiency are essential, choosing the right metal fabrication service can make all the difference.

The Importance of Professional Metal Fabrication

Metal fabrication is more than just cutting and shaping metal—it’s a combination of engineering, craftsmanship, and technology. With the right expertise, fabricated metal components can withstand extreme conditions, improve efficiency, and enhance structural integrity.

Key Benefits of Metal Fabrication Services:

✔ Customization – Tailored solutions to meet specific design and functional needs.

✔ Durability – High-quality materials and expert craftsmanship ensure longevity.

✔ Precision Engineering – Advanced technology guarantees accuracy in every cut and weld.

✔ Cost Efficiency – Professional fabrication reduces waste and improves production efficiency.

Sheet Metal Work: Crafting Precision Components

Sheet metal fabrication involves cutting, bending, and assembling thin metal sheets into functional parts. It’s a vital process in various applications, including HVAC systems, automotive manufacturing, and architectural designs.

Common Uses of Sheet Metal Fabrication:

- Ductwork & Ventilation Systems – Custom-fitted for efficiency.

- Architectural Elements – Decorative panels, railings, and cladding.

- Automotive Parts – Lightweight and durable components.

- Industrial Equipment – Custom enclosures, casings, and machine parts.

For expert sheet metal fabrication, A & D Fabricating provides tailored solutions, ensuring high precision and superior quality.

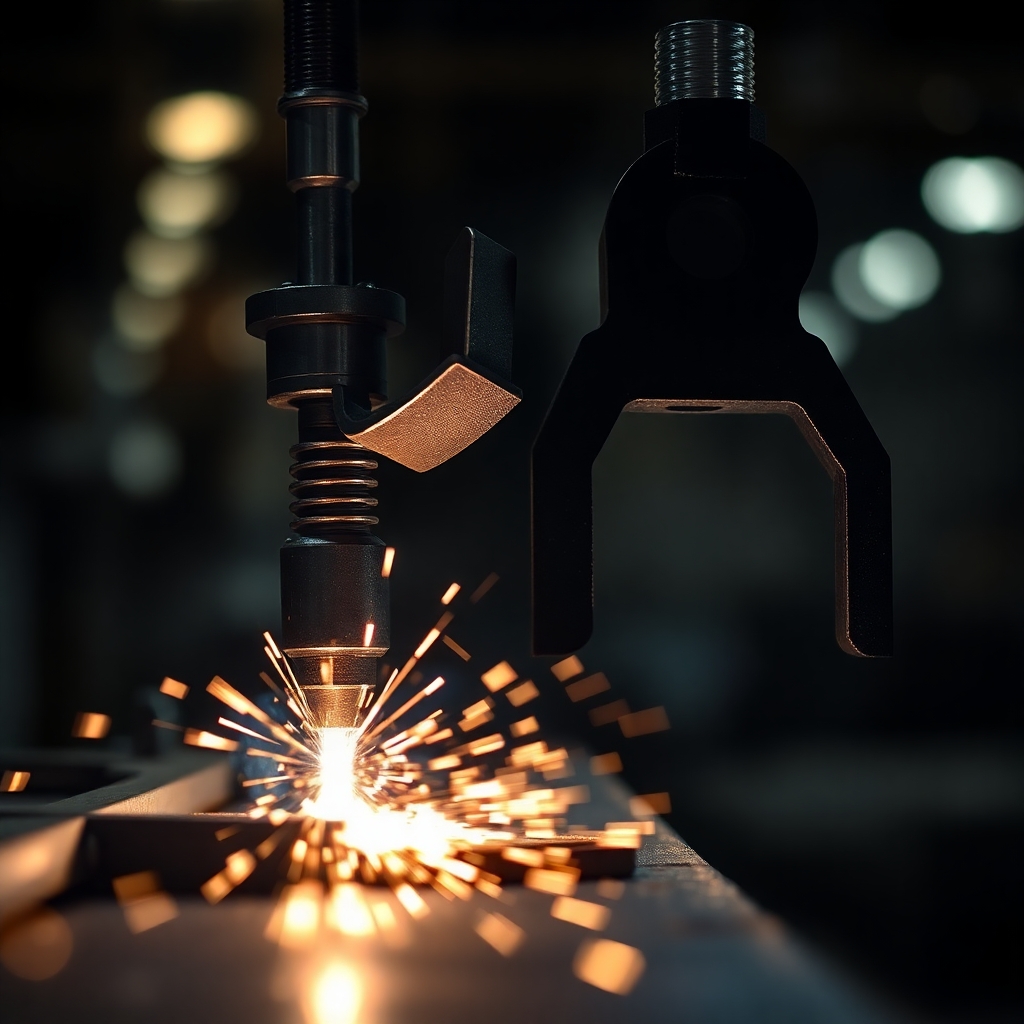

Welding Work: Strengthening Structures with Expertise

Welding is a fundamental part of metal fabrication, ensuring that components are securely fused for maximum durability. Depending on the project, different welding techniques are used to create seamless, strong, and corrosion-resistant joints.

Types of Welding Techniques:

✔ MIG Welding – Ideal for heavy-duty applications with strong, clean welds.

✔ TIG Welding – Delivers precision and control for fine metalwork.

✔ Arc Welding – Commonly used in construction and repair work.

✔ Spot Welding – Perfect for thin metal sheets and small components.

Metal Forging: Shaping Strength and Durability

Forging is a process that involves heating and shaping metal to achieve high-strength components. Unlike casting or machining, forging enhances the metal’s grain structure, making it more resilient and durable.

Industries That Rely on Metal Forging:

- Aerospace & Defence – High-strength parts for aircraft and military equipment.

- Automotive – Engine components, drive shafts, and transmission parts.

- Industrial Machinery – Heavy-duty gears, tools, and fasteners.

Custom Metal Parts: Tailored Solutions for Every Industry

Custom metal fabrication is essential for businesses that require specialized components that aren’t available off the shelf. Whether it’s a unique bracket, machine part, or decorative metal piece, precision fabrication ensures a perfect fit.

Why Invest in Custom Metal Fabrication?

✔ Made-to-Measure Fit – Components designed to exact specifications.

✔ High-Quality Materials – Metals selected based on strength and durability.

✔ Optimized Performance – Parts engineered for specific applications.

✔ Fast Prototyping & Production – Quick turnaround times for urgent projects.

For businesses looking for custom metal solutions, working with experienced metal fabricators ensures top-tier quality and efficiency.

Trailer Repairs & Manufacturing: Built for Strength and Reliability

Trailers endure heavy loads and long-distance travel, making regular maintenance and high-quality manufacturing essential. Metal fabrication services help in both repairing and building trailers that meet safety standards and durability requirements.

Trailer Fabrication & Repair Services:

✔ Structural Reinforcements – Strengthening frames and load-bearing components.

✔ Axle & Suspension Repairs – Ensuring smooth and safe performance.

✔ Custom Trailer Builds – Designed for specific commercial or personal needs.

✔ Welding & Metalwork Repairs – Fixing cracks, rust damage, and worn-out parts.

Choosing the Right Metal Fabrication Service in Toronto

Not all metal fabrication companies offer the same level of expertise, so selecting the right one is crucial for ensuring quality and durability.

Factors to Consider When Hiring a Metal Fabricator:

✔ Experience & Expertise – Years of industry knowledge and skilled professionals.

✔ State-of-the-Art Equipment – Advanced machinery for precision work.

✔ Material Selection – High-quality metals for durability and performance.

✔ Timely Delivery – Efficient project completion without compromising quality.

Innovative Metal Fabrication for Every Project

From sheet metal work and welding to trailer repairs and custom metal components, professional metal fabrication services in Toronto offer reliable solutions for various industries. By choosing skilled fabricators, businesses and individuals can ensure strength, precision, and long-lasting performance in every project.